In Myanmar, a large amount of rice husks are discarded into roadsides and rivers. In addition, rice mills also have a large amount of rice husks every year. The discarded rice husks have a serious impact on the local environment.

Our Burmese customer has a keen business vision. He wants to turn discarded rice husks into profits, and also contributes to the local environment to achieve a win-win situation.

Biomass pellet machine is also called straw pellet machine, sawdust pellet machine, sawdust pellet machine, etc. It produces pellet fuel raw materials mainly agricultural and forestry wastes, including straw, sawdust, sawdust, straw, etc. Extruded into rod-shaped biomass pellet fuel, biomass fuel has many advantages over coal. Specific analysis is as follows:

Pellet fuel meets China’s environmental protection requirements and is a new type of biomass energy.

The biomass pellet fuel has a uniform shape, small volume and high density, which is convenient for transportation and storage.

The pellet fuel produced by the sawdust pelletizer does not contain harmful chemicals, and the ash can be directly used for crops, and the ash is rich in organic potassium. After the coal is burned, it will produce a large amount of sulfur-phosphorus compounds and coal impurities, which will pollute the land everywhere, which is not conducive to the construction of environmental protection in Myanmar.

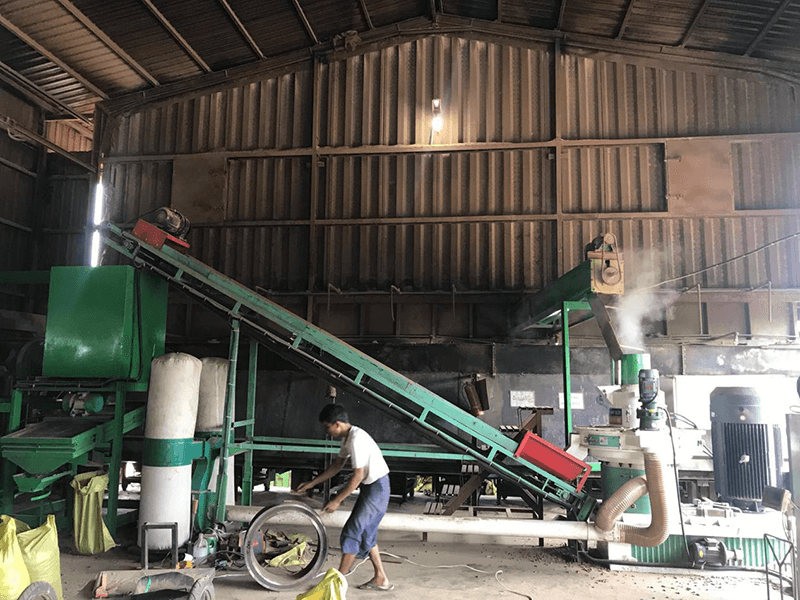

The 1.5-2 t/h rice husk pellet machine is located in Myanmar.

The raw material is waste rice husk, the moisture is 10-15%

Customers turn waste rice husks into biomass fuel

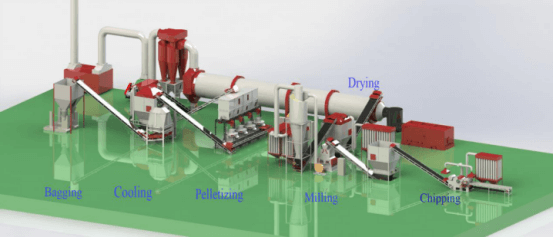

We will offer whole production line design solution according to the information provided by customers. Meanwhile, we can offer the equipment location diagram according to the size of customers’ factory.

All processes in a wood pellet production line:

Debarking — Splitting — Chipping — Milling — Pelletizing — Cooling —Bagging

Raw material for making biomass pellet could be:

A. Wood waste: sawdust, sharvings, tree branches, leaves, barks, wood offcut from woodworking factory; bamboo, palm fiber, etc

B. Agricultural residues: rice husk, seeds shells, peanut shells, halm, wheat straw, corn stalk, hops, tobacco dross, cotton stalks, alfalfa grass, bagrass, palm fiber, cashew shell, alfalfa grass, etc

Raw material for making feed pellet could be:

A: Agricultural residues, grass

B: Crops

why choose kingoro?

A government-supported enterprise specialized in manufacturing machines for 25 years.

Awarded various certificates Awarded various certificates of quality, advanced enterprise

We are dedicated to improve the earth environment by researching

and manufacturing more and more clean energy equipment.

Post time: Mar-14-2020