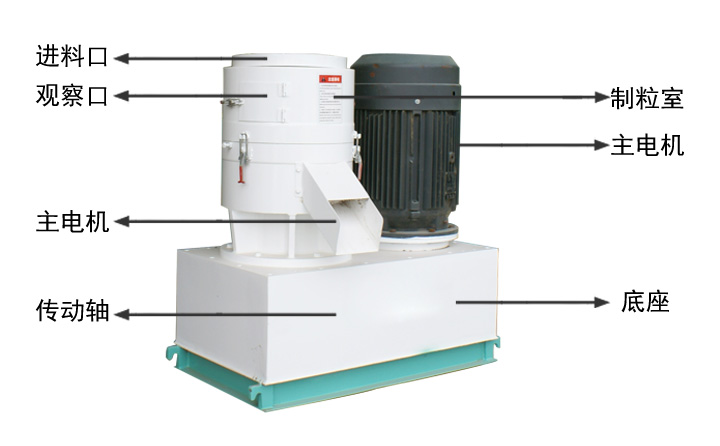

1. What is a flat die granulator The flat die granulator adopts two-stage transmission of belt and worm gear, with stable rotation and low noise. Feeding depends on the gravity of the material itself to avoid blockage. The speed of the main shaft is about 60rpm, and the line The speed is about 2.5m/s, which can effectively remove the gas in the material and increase the tightness of the product.

Due to the low linear speed, the noise generated during operation and the wear of parts are reduced at the same time, the material can be dried in and out without drying, and the differential gear and universal joint drive are adopted, which has low energy consumption, high output and convenient operation. .

The roller bearing has permanent lubrication and special sealing, which can prevent the lubricant from contaminating the material and reduce the loss of lubricant during the granulation process. Choose, users can choose flat die with different apertures and compression ratios according to different needs to obtain the best technology and economic benefits.

The flat die pellet machine can be widely used in animal husbandry, large, medium and small breeding plants, feed factories and brewing, sugar, paper, medicine, tobacco factories and other industries to regranulate organic waste. Ideal equipment for production enterprises.

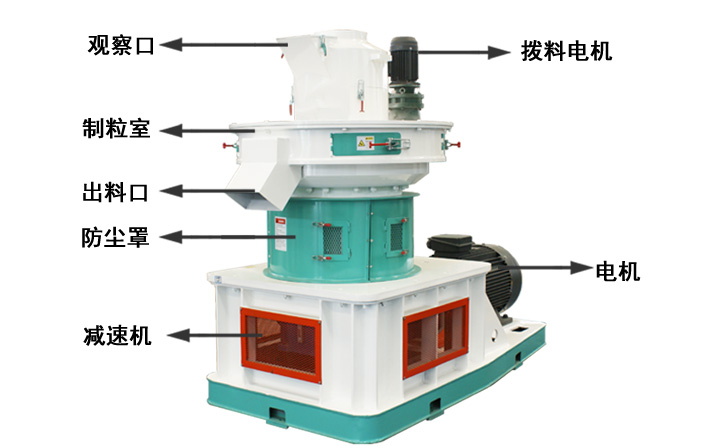

2. What is a ring die pellet machine? It is a feed processing machine that directly presses particles from crushed materials such as corn, soybean meal, straw, grass, rice husk, etc. Ring die pellet machine is one of the feed pellet machine series equipment, which is widely used in large, medium and small aquaculture, grain and feed processing plants, livestock farms, poultry farms, individual farmers and small and medium-sized farms, farmers or It is used in large, medium and small feed processing plants.

The product has the following advantages:

1. The product has simple structure, wide adaptability, small footprint and low noise;

2. Powdered feed and grass powder can be pelleted without adding a little liquid, so the moisture content of pelleted feed is basically the moisture content of the material before pelleting, which is more convenient for storage;

3. It can be made into pellet feed for chicken, duck, fish, etc., which can obtain higher economic benefits than mixed powder feed;

4. Dry material processing produces feed pellets with high hardness, smooth surface and internal ripening, which can improve the digestion and absorption of nutrients;

5. The granule formation process can denature the pancreatic enzyme resistance factor in grains and beans, reduce the adverse effects on digestion, kill various parasite eggs and other pathogenic microorganisms, and reduce various worms and digestive system diseases. .

3. The difference between the ring die pellet machine and the flat die pellet machine

1. In terms of price: the price of the ring die pellet machine is higher than that of the flat die;

2. Output: The output of the current flat die pellet machine per hour ranges from more than 100 kilograms to 1000 kilograms, and it is not much higher, but the minimum output of the ring die pellet machine is 800 kilograms, and the high one can reach more than 20 kilograms. Ton;

3. Feeding method: the flat die granulator enters the pressing chamber vertically by the weight of the material itself, while the ring die granulator adopts a curved upper trough to roll and compress the feed, and rotates at a high speed point-to-point into the compression bin, that is, the raw material is sent to the pressing wheel just as well. Arrived, there is a view that this will cause uneven feeding, I personally think that this situation basically does not exist.

4. Particle finish and compression ratio: the die roll gap of the flat die granulator is usually 0.05~0.2 mm, and the flat die is usually 0.05~0.3. The adjustable range of the compression ratio of the flat die granulator is higher than that of the flat die granulator. The machine is larger, and the finish of the particles produced is better than that of the flat die; in addition, although there are some differences between the two in terms of pressure, discharge method, and pressure wheel adjustment method, as long as it is the equipment of the regular manufacturer, Can meet the qualified production requirements. Therefore, if your current requirements for granulation output and compression ratio are not high (below 800 kg per hour), it is recommended to use a flat-die granulator; It is better to choose a ring die.

Post time: Aug-16-2022